color steel corrugated sheet machine

Corrugated tile Roll Forming Machine are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and different kinds of greenhouses. What's more, equipment can be designed and manufactured as customers' requests.

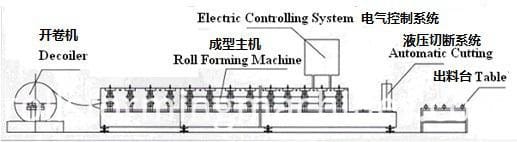

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Step formed→ Auto cutting→Products receiving

Parts of Roof Roll Forming Machine:

Components of corrugated roll forming machine production line

1. Manual Decoiler: set 1

2. Punching part: set 1

3. Main forming machine: set 1

4. PLC control sysem: set 1

5 . Hydraulic pump station: set 1

6. Post cut: set 1

7. Electric motor: set 1

8. Output table: set 1

Machine Description: Corrugated Sheet Roll Forming Machine

Quantity: 1 SET

Delivery time: 40 working days after receiving deposit

Container Type: One 20GP

Price(FOB TIANJIN): USD6500---25000

Usage of corrugated roll forming machine:

Control System: PLC with touch screen

Way Of Drive: 1.2 inch single chain

Roll material: 45# high grade steel

Shaft material: 45# high grade steel

Frame material: 300 H-high grade steel

Cutting blade material: Cr 12 high grade steel

Cutting type: hydraulic cutting

Lanugage system: Chinese ,English ,

Size of container: GP

Feature: high speed, low energy consumption

Parameters

Product name: Metal roofing roll forming machine

1. Suitable Material

Type: GI/PPGI/AL

Width: 1000/1200/1220/1250mm (Custom)

Thickness: 0.40-0.70mm

2. Product pecifications

Length: Any length

Length Tolerance: ±2mm/6m

3. Working Speed: 25 m/min (10 piece per min as 8 feet per piece) (Standard machine)

4. Control System: Mitsubishi/Siemens PLC& transducer (Custom)

5.Total Power: About 12KW

6.Total Weight: About 10.5T (Up to final design)

Packaging Details:

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Delivery Detail:

45 days after receipt of buyer's deposit

Looking for ideal Steel Sheet Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Color Steel Sheet Machine are quality guaranteed. We are China Origin Factory of Color Steel Corrugated Machine. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine

Mr. Cary xu

Mr. Cary xu